TM 5-3805-263-14&P-3

CRANKSHAFT

Check crankshaft screw threads, tapered ends and all

machined and ground surfaces for wear, scores, or

damage. Crankshaft journals which are out of round

should be replaced. Main bearing journals must be

maintained so bearings are snug fit. The oil seal ring

groove or grooves In crankshafts fitted with oil seal rings

must not be worn. The ring groove walls must have a

good finish and they must be square. Check to be sure

the oil passages are open and clean through the

crankshaft.

CONNECTING ROD BEARINGS

Check connecting rod bearings on crankshaft journals

for proper fit. Connecting rod caps are not

interchangeable. The locking slots of the connecting rod

and cap should be positioned adjacent to each other.

Clearance between the connecting rod journal and the

FIGURE 8

connecting rod bearing must not be less than 0.0003 in.

MEASURING CYLINDER BORES

or more than 0.0021 in.

CYLINDER BORES

Cylinder bores which are scored or out of round by more

MAIN BEARINGS

than 0.002 in. or tapered more than 0.003 in. should be

The sleeve bearing should be checked for scores and

replaced (Fig. 8).

wear and replaced if necessary.

Cylinder bores must be smooth, straight, and round.

Clearance between cast iron pistons and cylinder bores

UNLOADER MECHANISM

should be between 0.002 in. minimum and 0.004 in.

Used unloader mechanism should be replaced.

maximum (Fig. 20).

The new unloader pistons should be a loose sliding fit in

PISTONS

the unloader piston bores of the cylinder block.

Check pistons for scores, cracks or enlarged ring

grooves; replace pistons if any of these conditions are

REPAIRS DISCHARGE VALVES AND SEATS

found.

If discharge valve seats merely show signs of slight

Measure each piston with a micrometer in relation to the

wear, they can be dressed by using a lapping stone,

cylinder bore diameter to be sure the clearance is

grinding compound and grinding tool. Install new

between 0.002 in. minimum and 0.004 in. maximum.

discharge valves and valve springs.

Check fit of wrist pins on pistons and connecting rod

bushings. Wrist pin should be a light press fit in pistons.

To test for leakage by the discharge valves apply about

If wrist pin is loose fit, the pin, piston, or both should be

100 pounds of air pressure through the cylinder head

replaced.

discharge port and apply soap suds at the discharge

Check fit of wrist pin in connecting rod bushing by

valves and seats.

rocking the piston. This clearance should not exceed

0.001 5 in.

Leakage which will permit the formation of bubbles is

Replace the connecting rod if excessive clearance is

permissible.

found.

If excessive leakage is found, leave the air pressure

applied, and with the use of a fibre or hardwood dowel

and hammer, tap the discharge valves off their seats

several times. This will help the valves to seat and

should reduce any leakage.

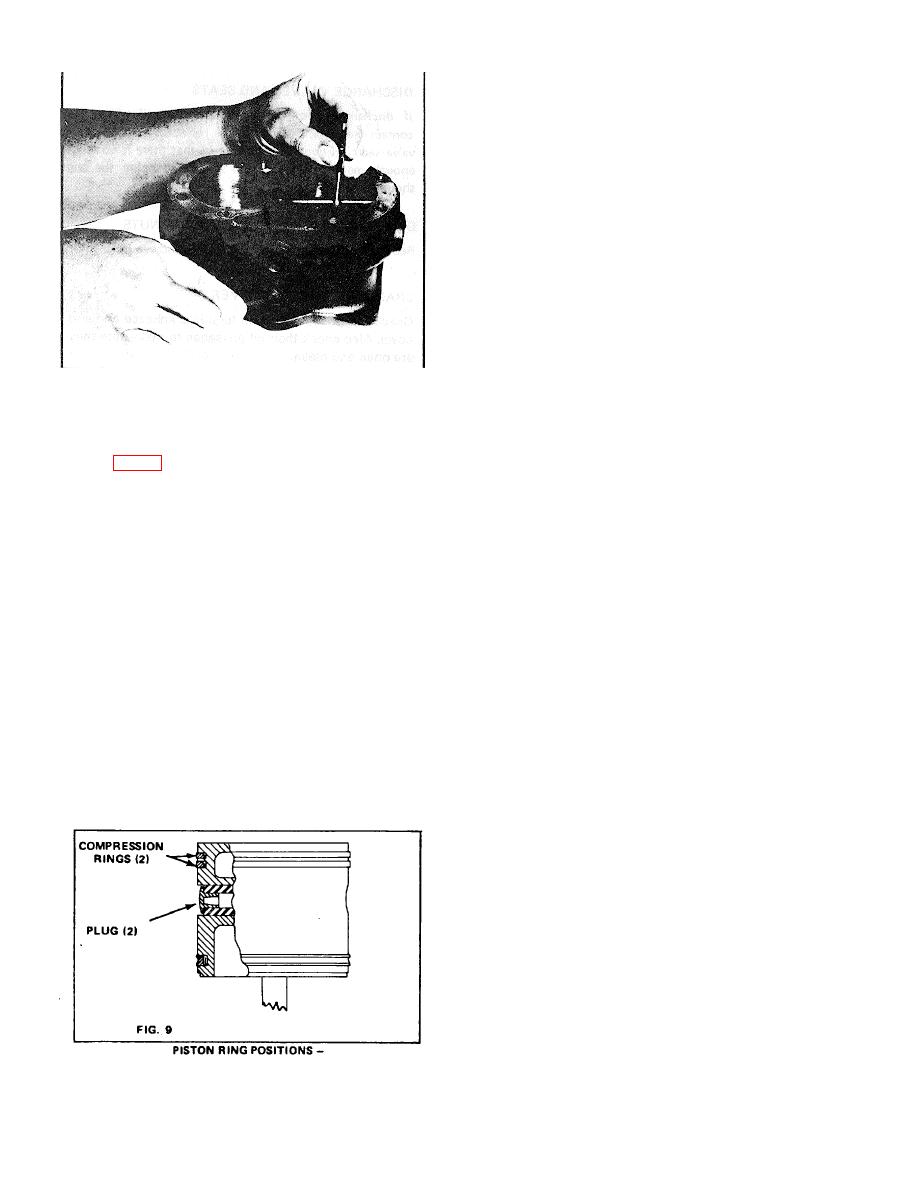

FIGURE 9 PISTON RING POSITION

3-138