TM 5-3805-263-14&P-3

Remove the cap screws securing the base plate. Tap

with soft mallet to break the gasket seal. Scrape off any

gasket material from crankcase and plate.

CONNECTING ROD ASSEMBLIES

(NOTE: Before removing the connecting rods, mark

each connecting rod and its cap. Each connecting

rod is matched to its own cap for proper bearing fit,

and these parts must not be interchanged.)

Straighten the prongs of the connecting rod bolt

lock strap and remove the bolts and bearing caps.

Push the piston with the connecting rods attached

out the top of the cylinders of the crankcase.

Replace the bearing caps on their respective

connecting rods. Remove the piston rings from the

pistons. If the pistons are to be removed from the

connecting rods, remove the plugs and press the

wrist pins from the pistons and connecting rods.

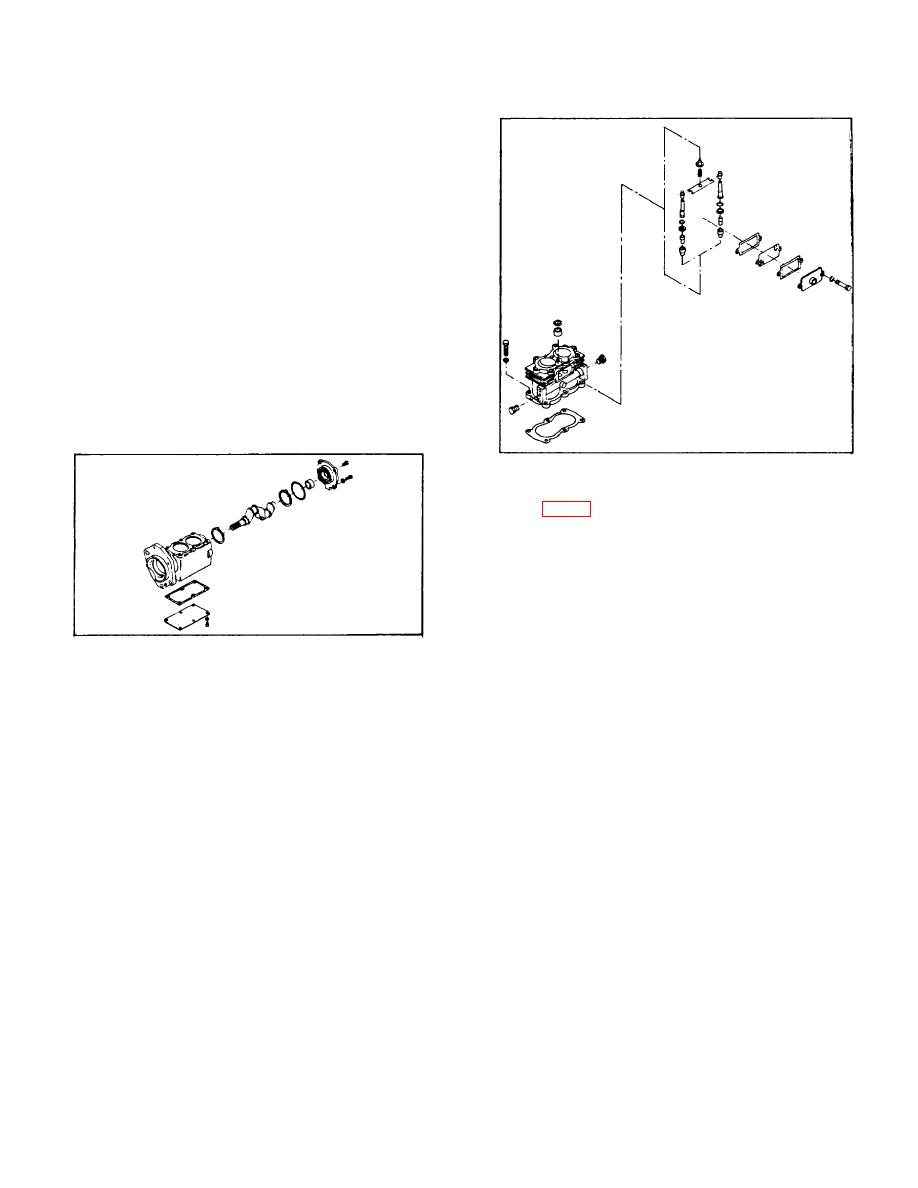

FIGURE 7 CYLINDER BLOCK EXPLODED VIEW

BLOCK (Fig. 7)

Remove the air strainer.

Remove cap screws securing cylinder block to

crankcase; separate crankcase and cylinder block and

scrape off gasket.

Remove unloader spring, spring saddle and spring seat

from cylinder block.

FIGURE 6 -CRANKCASE

Remove end cover, remove end cover seal.

Remove unloader guides and plungers and with the use

of shop air blow unloader pistons out of cylinder block

Remove the crankshaft from the crankcase. The

unloader piston bores.

compressor has a sleeve-type bearing In the end cover.

If the clearance between crankshaft journal and bearing

Remove inlet valve guides; inlet valve seats can be

exceeds .0065 in. the sleeve bearing should be replaced.

removed but only if they are worn or damaged and are

being replaced. Unloader bore bushings should be

inspected but not removed unless they are damaged.

3-136