TM 5-3805-263-14&P-3

AIR SYSTEM AND BRAKES

4.

Stop the engine, but do not turn the disconnect

switch off.

5.

While looking at the test gauge(s), push the brake

pedal down rapidly several times to release

pressure air.

6.

The electric buzzer and the indicator light for low air

pressure must operate at 60 + 6 psi (415 + 40 kPa).

7.

If the buzzer and/or light does not operate, or does

not operate at the correct pressure, turn the

disconnect switch off and check the electrical

connections for the buzzer, the light and the

pressure indicator(s). Check the bulb for the

indicator light.

8.

If necessary, connect a continuity light across the

terminals of the pressure indicator(s).

ROTOCHAMBER FOR PARKING BRAKE

NOTE: The pressure must be below the specifications of

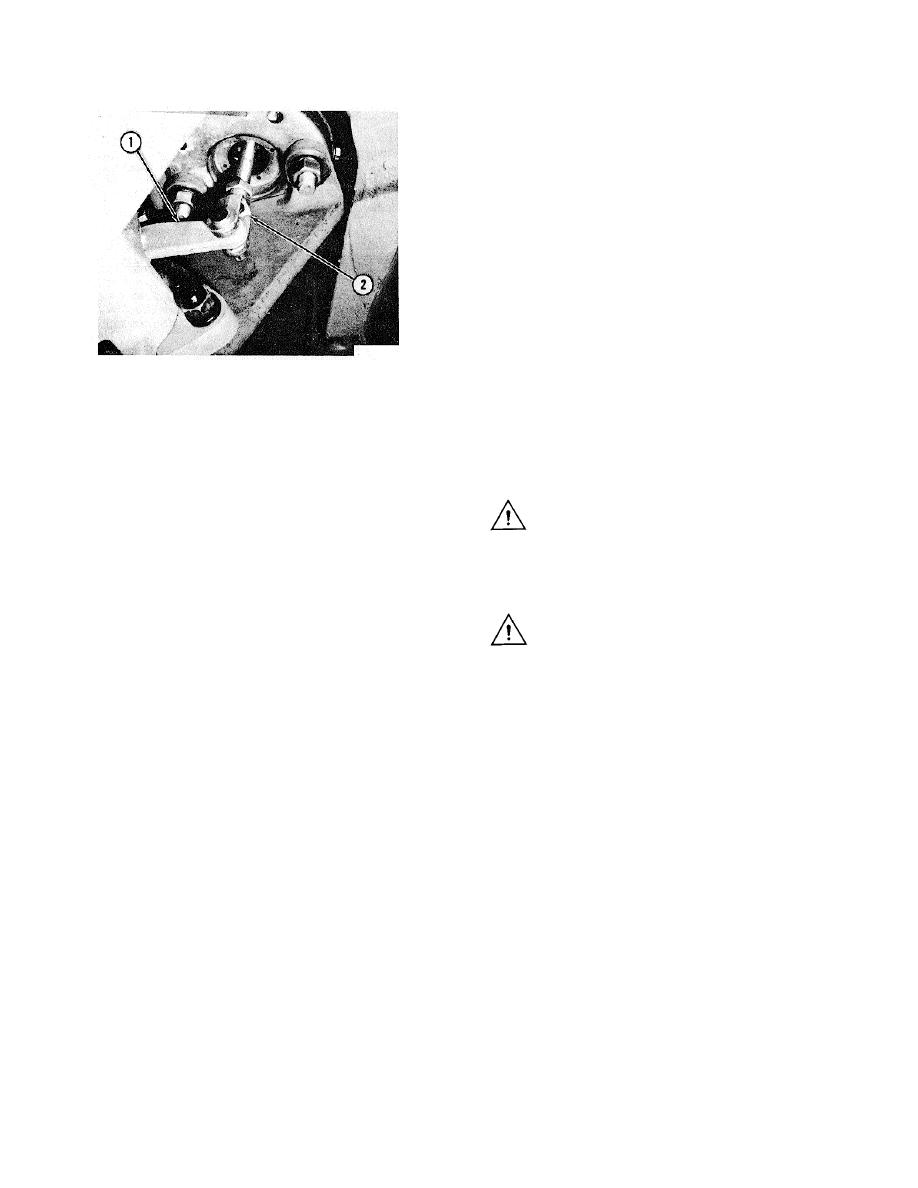

1. Lever. 2. Rod end.

the indicator.

Checking Electric Warning Systems

9.

If the continuity light does not operate, install a new

Stoplights

indicator.

1. Make sure all of the pressure air is released from

10. On machines with the two section air tank, check

the air tank.

the other indicator.

2. Push the brake pedal down fully.

3. Start the engine and look at the test gauge.

WARNING: Before disconnecting the test

gauge(s) and hose assemblies, make sure all of

NOTE: Look at the test gauge for the right section of the

the pressure air is released from the air tank.

air tank.

4. The stoplights must operate when the pressure is

CONTROL VALVE FOR

approximately 5 psi (35 kPa).

SERVICE BRAKES

5. Release the brake pedal.

WARNING: A change in braking characteristics

6. If the stoplights do not operate or do not operate at

or a low pressure warning may be an indication

the correct pressure, stop the engine and check the

of a failure in one of the brake circuits. The

stoplight bulbs, the electrical connections for the

machine should not be operated until repairs

stoplight switch on the brake control valve.

have been made and all circuits have been

7. If necessary, install a new stoplight switch.

checked. Always check the brakes after brake

repair before the machine is put back into use.

Pressure Indicator(s) for Low Air Pressure

1. Start the engine.

Every 300 service hours, clean around the pedal,

2. The electrical buzzer and the indicator light for low

plunger boot and mounting plate. Lubricate the pedal

air pressure will operate until the pressure is above

roller, roller pin and hinge pin. Inspect the plunger boot

approximately 65 psi (450 kPa).

(1) and replace if damaged. Check the mounting plate

3. Let the pressure go up to approximately 100 psi

and pedal for correct installation and alignment.

(690 kPa).

Lubricate the plunger (2) with 5P960 Multipurpose-type

grease.

Every 2000 service hours inspect the inlet and

exhaust valves (5) and (7), O-ring seals, rubber spring

(3) and all other parts. Replace the parts that show wear

or damage.

3-129