TM 5-3805-263-14&P-3

Use two 8M2885 Pressure Gauges [O to 200 psi (O to

TESTING AND ADJUSTING

1380 kPa)] to check the delivery pressure for the service

brakes on both sides of the machine. Connect the

Push the brake pedal to several positions between fully

gauges to the delivery ports (4) and

released and fully applied. Check the delivery pressure

on the test gauges to see that it varies (changes), the

same amount for both left and right brakes with

movement of the brake pedal.

Make a full application of the brakes. Release the

brakes. The reading on the test gauges should go to 0

psi (O kPa) very fast when the brakes are released.

The delivery air pressure shown on both test gauges

with both air tank pressures the same, should be within 5

psi (35 kPa). This is normal for this valve.

Leakage Check

Make and hold a full application of the brakes, 115 to

140 psi (795 to 1000 kPa). Put a mixture of soap and

water on the exhaust port (8).Permissible leakage is a 1

inch (25.0 mm) bubble in three seconds. If the leakage

is more, repair the valve and test again.

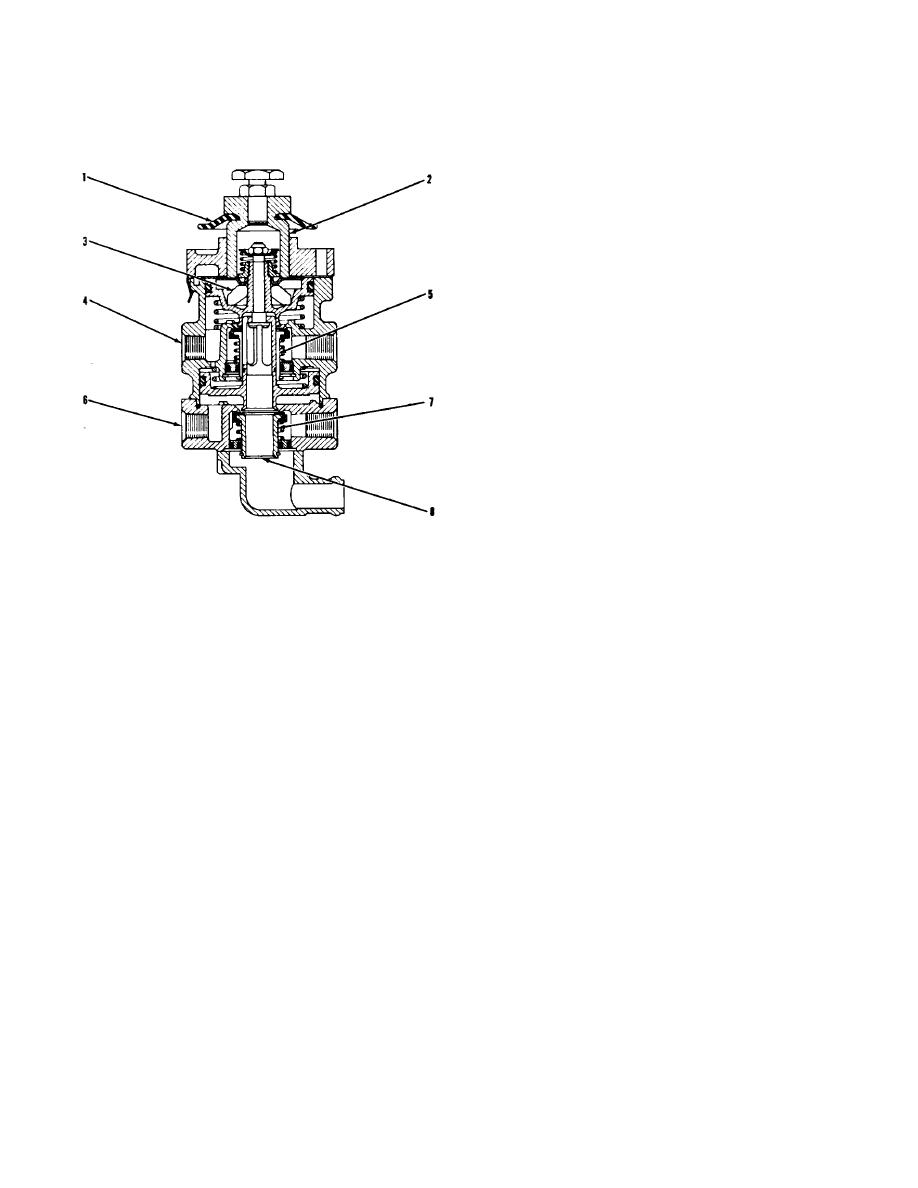

2G6680 CONTROL VALVE FOR SERVICE BRAKES

1. Plunger boot. 2. Plunger. 3. Rubber spring. 4.

Delivery port. 5. Inlet and exhaust valve. 6. Delivery

port. 7. Inlet and exhaust valve. 8. Exhaust port.

3-130