TM 5-3805-263-14&P-3

HYDRAULIC SYSTEM

AND STEERING

for the blade tip, and the ripper cylinder, have check

Valve Spool

valves with minimum resistance for the oil. There are

outlet chokes (1) in the check valves for the articulation

When either an adjustment for the location of valve

cylinders, the cylinder for center shift, and the lift cylinder

spool (1 6) is made, or when the valve spool is to be

for the blade on the right side of the machine. The check

removed, the housing and lever (9) must be removed

valve for the lift cylinder on the left side of the machine,

from the valve section.

has outlet chokes and also a relief valve in the passage

Cap lock (4) is removed when the adjustment for the

to the rod end of the lift cylinder.

location of the valve spool is made. The location for

A piston (5) that does not move easy in the check

valve spool (16) is correct when plug (3) is against the

valve is a cause for a hydraulic cylinder to move too

retainers and there is no end clearance for the valve

slow. Outlet chokes (1) that will not move away from the

spool.

fittings (2) is a cause for a hydraulic cylinder to move too

When plug (3) is not against the retainers, the unit of

slow. Balls (6) and seats (7) with rough surfaces is a

valve spool (16), spring (13) and retainers (2) have end

cause for cylinder rod drift.

clearance. When plug (3) is turned in too far, and it

moves the retainers at one end of spring ( 13) too near

the retainers at the other end of the spring, valve spool

(16) has end clearance between the retainers.

Install cap lock (4) when the adjustment for the

location of the valve spool is correct.

It may be necessary to turn the retainers at the top to

a position where the end of lever (9) can be installed in

the hole in the end of valve spool (1 6).

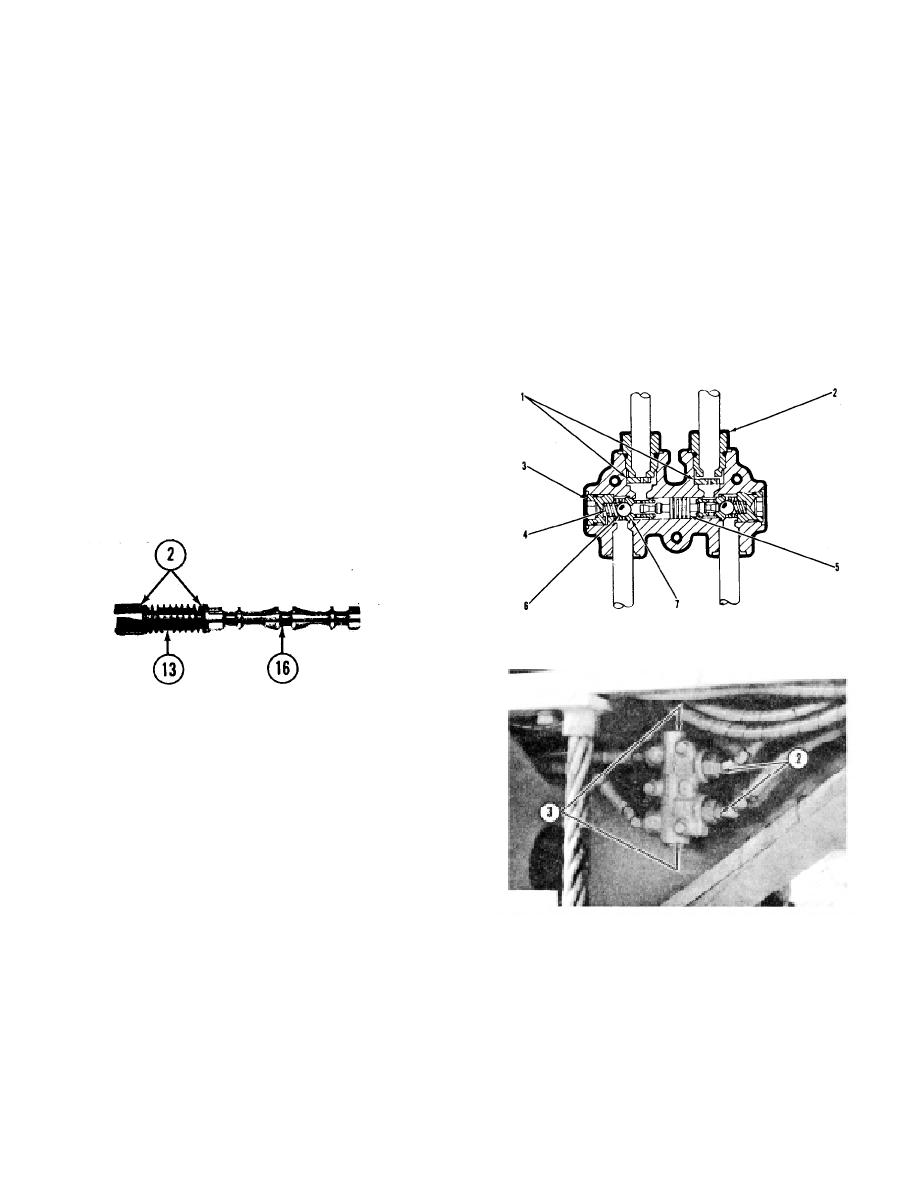

LOCK CHECK VALVE

1. Outlet chokes. 2. Fittings (two). 3. Plug (two). 4. Spring

(two). 5. Piston. 6. Ball (two). 7. Seat (two).

VALVE SPOOL

2. Retainers (two parts for each retainer). 13. Spring. 16. Valve

spool.

Valve spool (16), spring (13) and retainers (2) are

removed as a unit when either cover (21) is removed, or

cap lock (4) and plug (3) are removed from the valve

section.

Use new O-ring seals when the parts are installed in

the valve section.

LOCK CHECK VALVE

LOCK CHECK VALVE

There are three types of lock check valves in the

(For articulation cylinders)

hydraulic system. The piston (5), the seats (7), the

2. Fittings. 3. Plugs.

springs (4), and the plugs (3) in each of the three types

of check valves are the same. The leaning wheel

cylinder, the cylinder to side shift the blade, the cylinders

3-27