TM 5-5805-263-14&P-3

HYDRAULIC SYSTEM

Pump (16) gets oil through a large line from tank (I). The

AND STEERING

oil from pump (16) goes through line (4) to unloading

valve (3). The unloading valve is part of the combination

valve. The pump oil in the combination valve goes to all

of the control valves in the hydraulic system.

VARIABLE DISPLACEMENT PUMP

The variable displacement pump is an axial piston pump.

The change in the output (displacement) is automatic.

The length of the stroke for the pistons is the control for

the output (displacement) of the pump. With a decrease

in the length of the stroke for the pistons, the output of

the pump is less. The movement of a swashplate in the

pump is the control for the length of the stroke for the

pistons. When the engine is stopped, a spring on a

valve in the pump keeps tle swashplate at the maximum

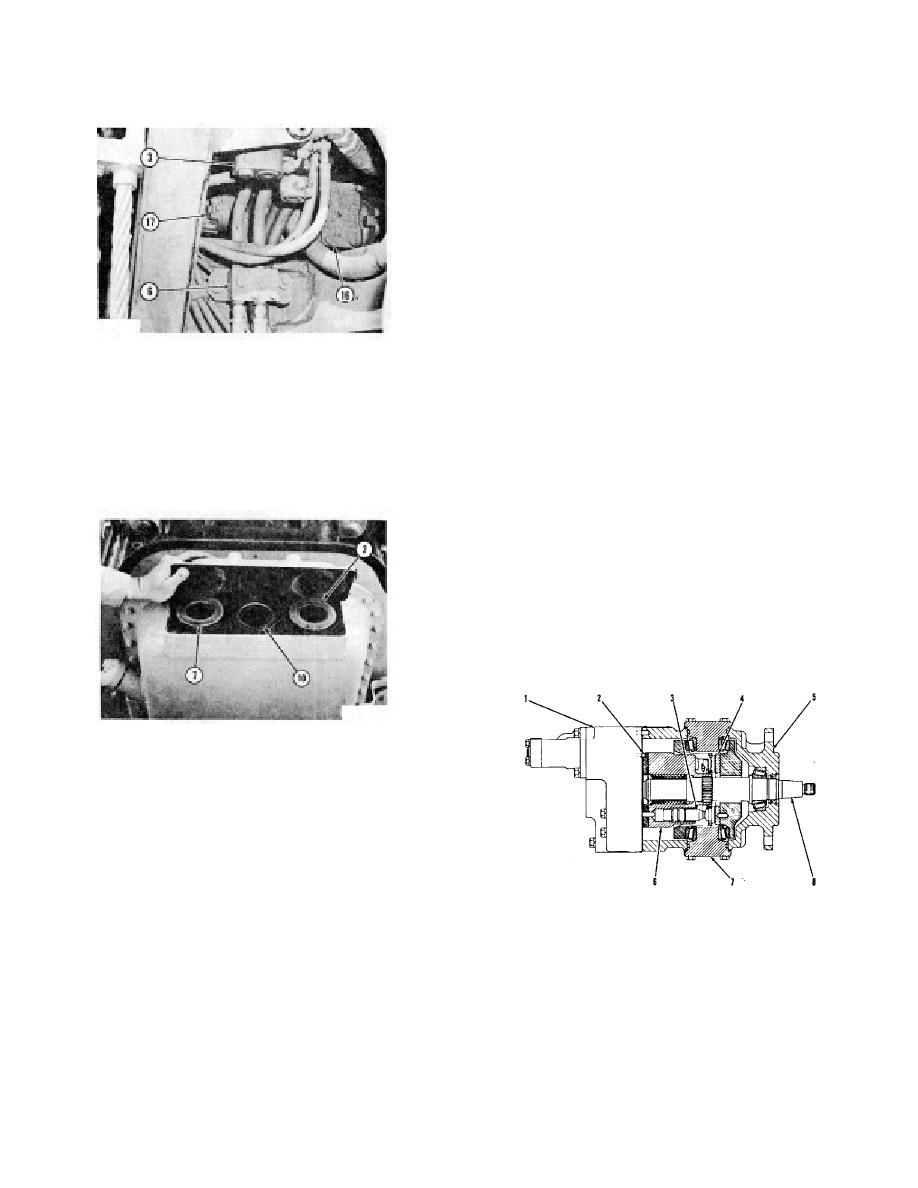

HYDRAULIC PUMP

angle (maximum length of the stroke for the pistons).

(Seen from left side of machine)

When the engine is running, oil at the outlet pressure of

3. Unloading valve (part of the combination

the pump is in the valve against the spring. When there

valve). 6. By-pass valve for oil cooler. 16.

is an increase in the pressure of the oil from the pump

Variable displacement pump. 17. Pump for oil

outlet, the force of the oil pressure in the valve against

to the oil cooler. The oil from the hydraulic

the spring is more and the spring gets compression

cylinders and hydraulic motor goes through filter

(shorter length). As the spring length gets shorter, the

(7), strainer (10) and into the tank.

swashplate moves toward minimum angle and the

output (displacement) of the pump is less.

The pump has two pressure settings. The load on the

hydraulic components causes the pressure setting of the

pump to change. An oil line, from the oil circuits to the

components, connects to a valve in the pump. The

pump operates at the low setting until more oil pressure

is needed for the component to move the load. When

the pressure of the oil to the component and in the line to

the valve in the pump gets an increase. the valve in the

pump

MANIFOLD FOR TANK

2. Filter (element). 7. Filter (element). 10. Strainer.

Each filter (2) and (7) has a bypass valve. If the filter

element is full of dirt, and oil can not go through the

element, the pressure of the oil gets an increase which

opens the bypass valve. The oil through the bypass

valve goes through strainer (10) and into tank (1). Each

filter has an indicator that shows when the filter element

is dirty.

Bypass valve (6) is for cooler (5). The bypass valve

VARIABLE DISPLACEMENT PUMP

opens when the pressure of the oil from pump (17) is

1. Head assembly. 2. Port plate. 3. Piston (nine). 4.

more than the pressure setting of the bypass valve. Dirt

Thrust plate. 5. Pump body. 6. Barrel assembly. 7.

in oil passages in cooler (5) will cause an increase in the

Swash-plate. 8. Drive shaft.

pressure of the oil from pump (17). The oil in the

hydraulic system can get too much heat if the oil from

pump (17) goes through the open bypass valve (6) and

not through cooler (5).

3-5