TM 5-3805-261-23-2

HYDRAULIC PUMP ASSEMBLY REPAIR - CONTINUED

0330 00

ASSEMBLY - CONTINUED

15.

Install two bearings (103) in oil on two covers (107).

16.

Install one of two new preformed packings (104) and enough shims (105 and 106) to obtain a shim thickness of 0.015 in.

(0.38 mm) on one of two covers (107).

17.

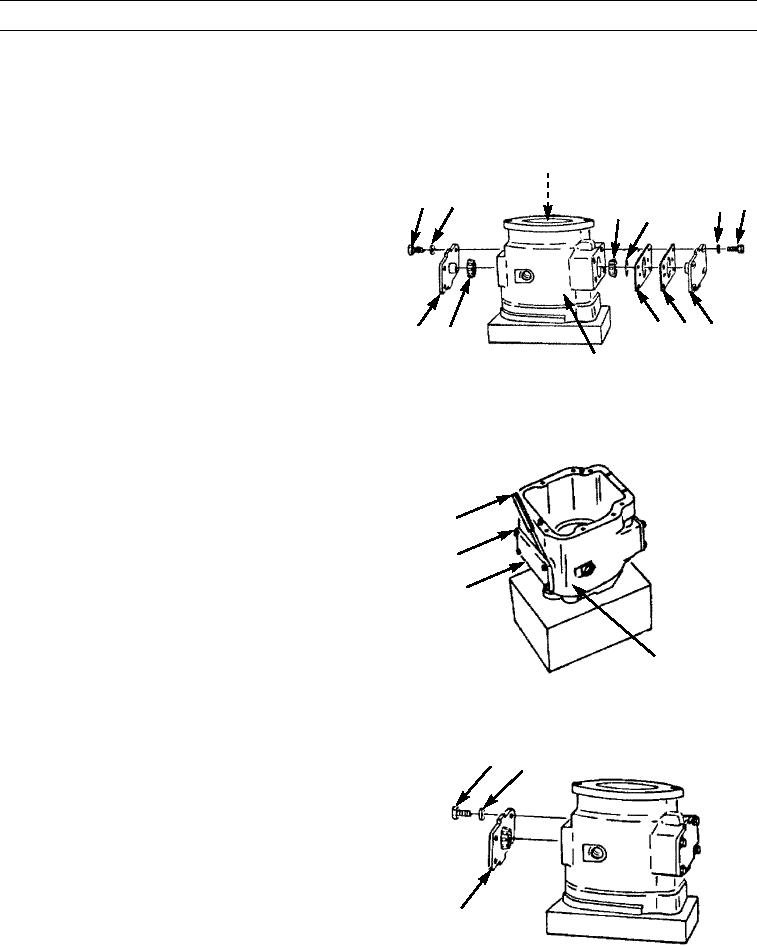

Position one cover (107) on body (62).

120

18.

Install four of eight lockwashers (109) and bolts (108).

109

108

109 108

Tighten bolts to 32 lb-ft (43 Nm).

103 104

19.

Position second cover (107) on opposite side of body

(62) with shim(s) (105 and 106).

20.

Install remaining four of eight lockwashers (109) and

bolts (108). Tighten bolts evenly in a clockwise direc-

tion to 40 lb-in. (4.5 Nm) in steps of 10 lb-in (1.1 Nm).

Move pump housing (120) back and forth while tight-

105 106 107

107 103

ening bolts.

62

397-1515

21.

Use feeler gauge to measure gap between body (62)

and cover (107) without shims. Measure at four bolt

(108) locations. Note the average thickness and add

0.008 in (0.02 mm). This will be the total shim thick-

FEELER

GAUGE

ness to be added to cover without shims. If the thick-

ness of shims required is less than 0.005 in. (0.13 mm)

108

and more than 0.025 in. (0.64 mm), add thickness of

the shims required from feeler gauge measurement

107

plus 0.008 in. (0.02 mm) to the 0.015 in. (0.38 mm)

shim thickness of the other cover. Divide the total

thickness of the shims evenly and install the same

thickness of shims on each cover.

62

397-1516

22.

Remove four bolts (108), lockwashers (109), and

108 109

cover (107) without shims.

107

397-1517

0330 00-16