TM 5-3805-293-23-3

0044

MARGIN PRESSURE ADJUSTMENT CONTINUED

8. Start engine (TM 5-3805-293-10).

9. Operate implement controls for 3 to 10 minutes at low idle in order to raise the hydraulic oil temperature to

normal operating temperature range (TM 5-3805-293-10).

10. Operate engine at wide open throttle (TM 5-3805-293-10).

N OT E

Do not allow machine to be in stalled condition for more than 10 seconds.

11. Operate the circle drive and rotate the blade at full speed (TM 5-3805-293-10) until fully actuated (stalled

condition).

12. Pressure reading should be 305 15 psi (2,100 100 kPa).

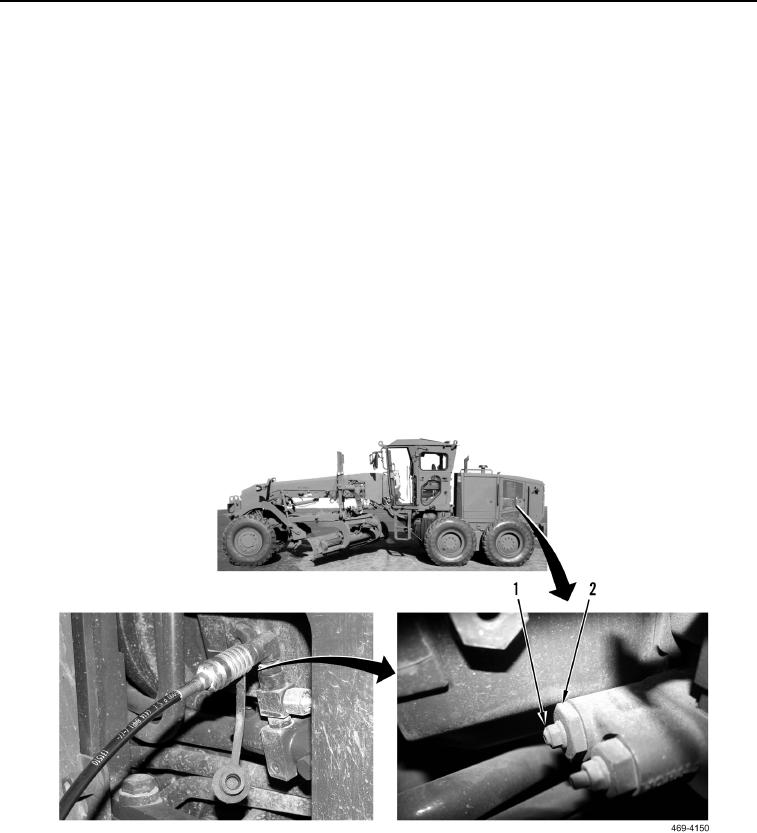

13. If pressure reading is incorrect, loosen locknut (Figure 96, Item 2) on adjustment screw (Figure 96, Item 1).

Turn adjustment screw counterclockwise in order to decrease pressure setting. Turn adjustment screw 1/4 turn

beyond estimated adjustment position and then back to estimated adjustment position.

14. Tighten locknut (Figure 96, Item 2) while holding adjustment screw (Figure 96, Item 1).

15. Stop engine (TM 5-3805-293-10).

16. Repeat steps 8 through 15 until correct pressure reading is obtained.

Figure 96. Adjustment Locknut and Screw.

0044