TM 5-3805-293-23-2

0035

FUEL QUALITY TEST

00035

C AU T I O N

It is important to maintain extreme cleanliness when working on fuel system, since even

tiny particles can cause engine or fuel system problems. Entire engine should be washed

with a high pressure water system to remove dirt and loose debris before starting a repair

on fuel system. Ensure no high pressure water is directed at seals for injectors. Failure to

follow caution may result in damage or contamination of fuel system.

1. Check for water in fuel/water separator bowl.

a. If contaminated drain fuel/water separator (TM 5-3805-293-10).

b. If not contaminated, proceed to step 2.

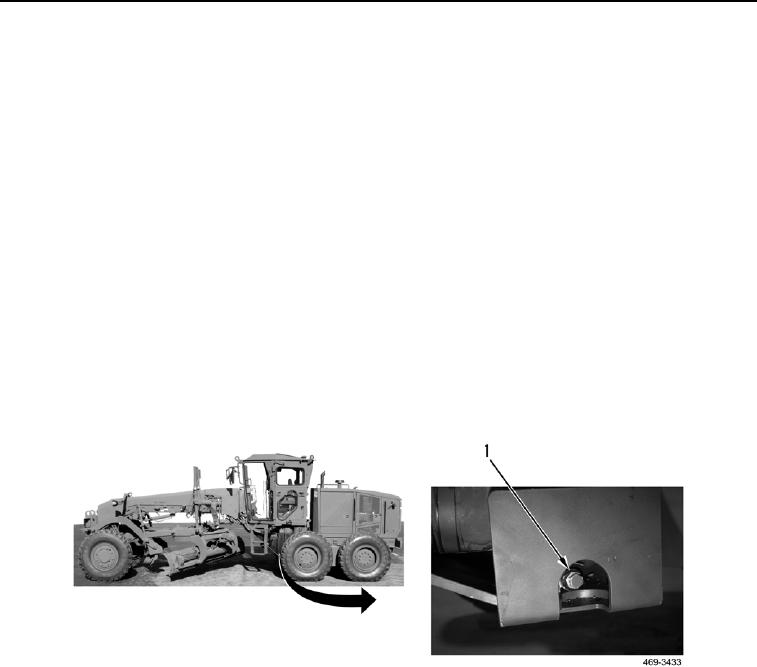

2. Position sample container under fuel tank drain plug (Figure 3, Item 1).

WARN I N G

Do not remove adapter from fuel tank when removing drain plug. Flow of fuel from fuel

tank will not be controllable if adapter is removed. Failure to follow this warning may result

in injury to personnel.

3. Slowly open fuel tank drain plug (Figure 3, Item 1) to allow a sample fuel to drain.

Figure 3. Fuel Tank Drain Plug.

0035

4. Tighten fuel drain plug (Figure 3, Item 1).

5. Visually inspect fuel sample for contaminants. If fuel is black, brown, and/or similar to sludge this can be an

indication of growth of bacteria or oil contamination. In cold temperatures, cloudy fuel indicates fuel may not be

suitable for operating conditions.

a. If contamination is detected, drain fuel system (WP 0229) and replace primary fuel filter (WP 0174) and

secondary fuel filter (WP 0073).

b. If no contamination is detected, fuel quality is OK.

END OF TASK