TM 5-3805-293-23-2

0028

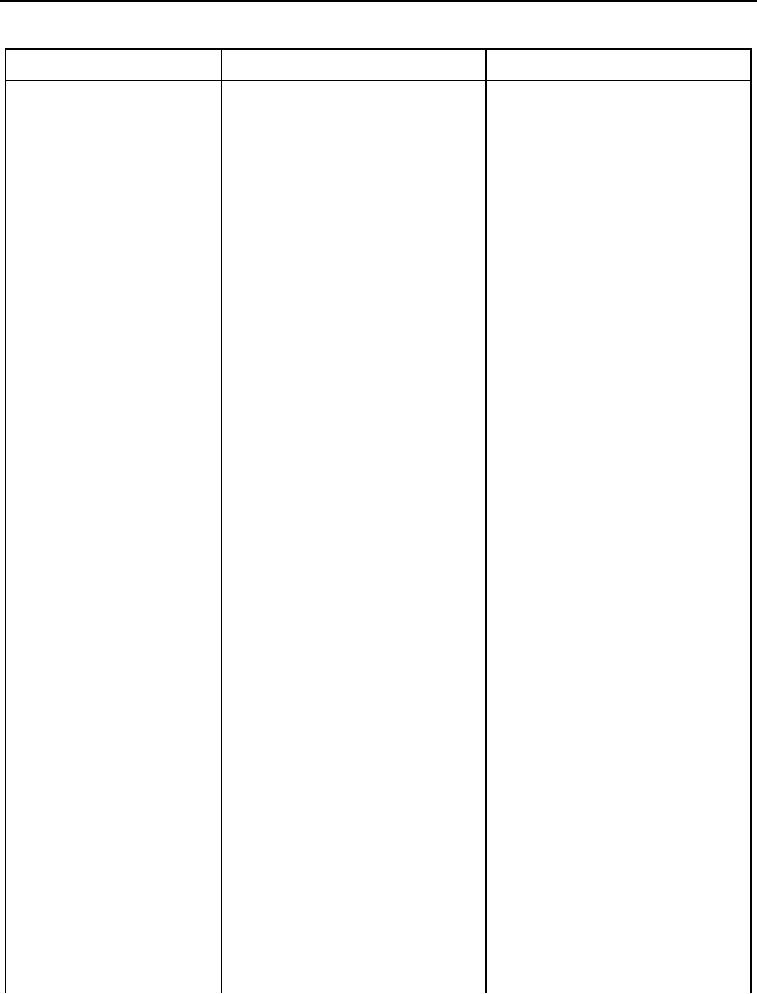

Table 1. Implement Code (2146-02 to 2156-08) Troubleshooting Procedures - Continued.

CDI FMI CODE

TEST OR INSPECTION

CORRECTIVE ACTION

2154-03 Blade Sideshift

Resistance 5.0 Ohms or Greater -

Lever Position Sensor Volt-

Replace cab lower wiring harness

age Above Normal - Contin-

(WP 0266).

ued

Proceed to step 5.

5. Using MSD (WP 0006), select

2154-03 Code Active - Repeat

Implement 120M ECM and verify

troubleshooting code from the

2154-03 is not active.

beginning.

2154-03 Code Not Active -

Troubleshooting complete.

Test Step 6. Test Signal Voltage to

Sensor.

1. Using digital multimeter, test for

Voltage Between 13.5 to 14.5 Volts -

voltage between harness connec-

Replace RH joystick (WP 0283).

tor connector PE-C8 (WP 0009,

Proceed to step 2.

Figure 50) terminal 7 and terminal

Voltage Out of Specifications of

3. Voltage should be between

13.5 to 14.5 Volts - Proceed to Test

13.5 to 14.5 volts.

Step 7.

2154-03 Code Active - Repeat

2. Using MSD (WP 0006), select

troubleshooting code from the

Implement 120M ECM and verify

beginning.

2154-03 is not active.

2154-03 Code Not Active -

Troubleshooting complete.

Test Step 7. Test for Open Cab

Lower Wiring Harness.

1. Turn ignition switch and battery

disconnect switch to the OFF

position.

2. Disconnect the cab lower wiring

harness connector P-C41 (WP

0009, Figure 68) from implement

ECM J1 (WP 0009, Figure 69)

(WP 0266).

3. Disconnect the cab lower wiring

harness connector P-C39 (WP

0009, Figure 70) from implement

ECM J2 (WP 0009, Figure 71)

(WP 0266).

4. Connect jumper wire between cab

lower wiring harness connector

PE-C8 (WP 0009, Figure 50) ter-

minal 7 and terminal 3.

0028-61