TM 5-3805-293-23-2

0023

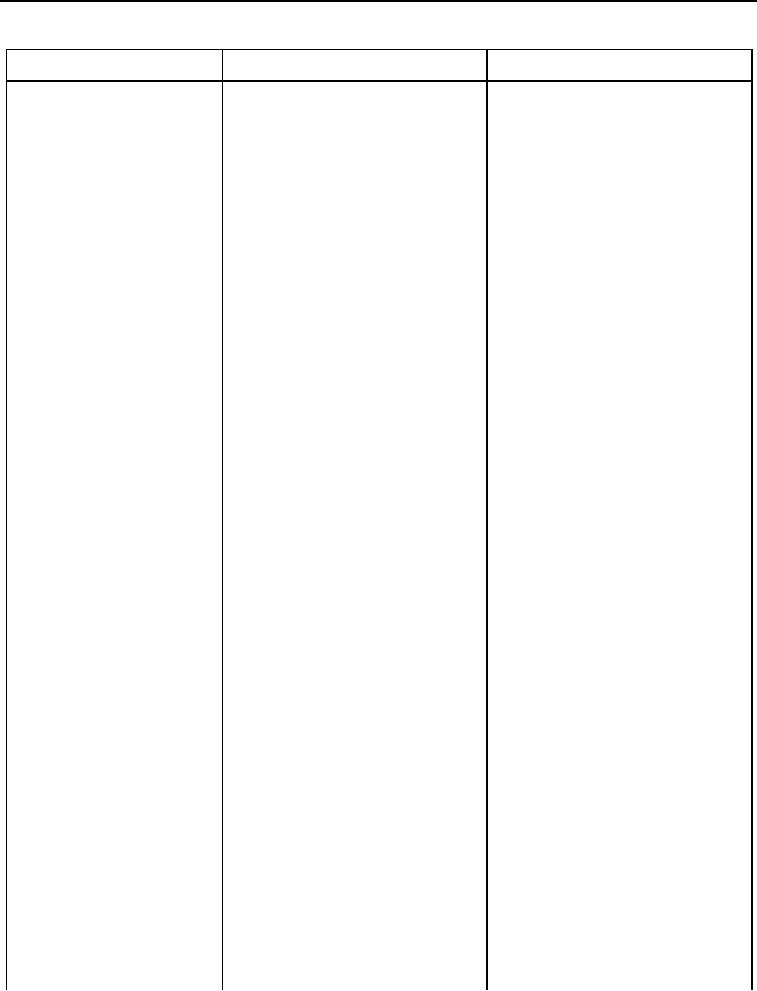

Table 1. Cab Electrical Troubleshooting Procedures - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

13. One or Both Brake

2. While an assistant applies the

Resistance Less Than 5.0 Ohms -

Lights Do Not Operate,

brake, using digital multimeter,

Replace cab lower wiring harness

Turn Signals Operate

measure resistance between

(WP 0266).

Normally - Continued

brake light switch (WP 0009, Fig-

Proceed to step 3.

ure 332 terminal A and C. Resis-

Resistance 5.0 Ohms or Greater -

tance should be less than

Replace brake switch (WP 0291).

5.0 ohms.

Connect the control indicator harness

connector PE-C11 (WP 0009, Figure

287) to cab lower wiring harness con-

nector P-C11 (WP 0009, Figure 286)

(WP 0283).

Connect the control indicator harness

connector PE-C10 (WP 0009, Figure

288) to control indicator switch (WP

0009, Figure 289).

Proceed to step 3.

3. Turn control indicator switch to

Right and Left Brake Lights Do Not

position SER. DRIVE, have an

Operate - Repeat troubleshooting

assistant apply the service brakes

from the beginning.

(TM 5-3905-293-10) and observe

Right and Left Brake Lights Oper-

the brake lights from the rear of

ate - Troubleshooting complete.

the machine and verify both brake

lights operate.

Test Step 8. Check for Open Circuit

from Cab Lower Wiring Harness to

Cab Upper Wiring Harness.

1. Disconnect the RH turn relay (WP

0009, Figure 328) from RH turn

relay socket (WP 0009, Figure

329).

2. Connect jumper wire between RH

turn relay socket (WP 0009, Fig-

ure 329) terminals A2 and A1.

0023-72