TM 5-3805-293-23-2

0023

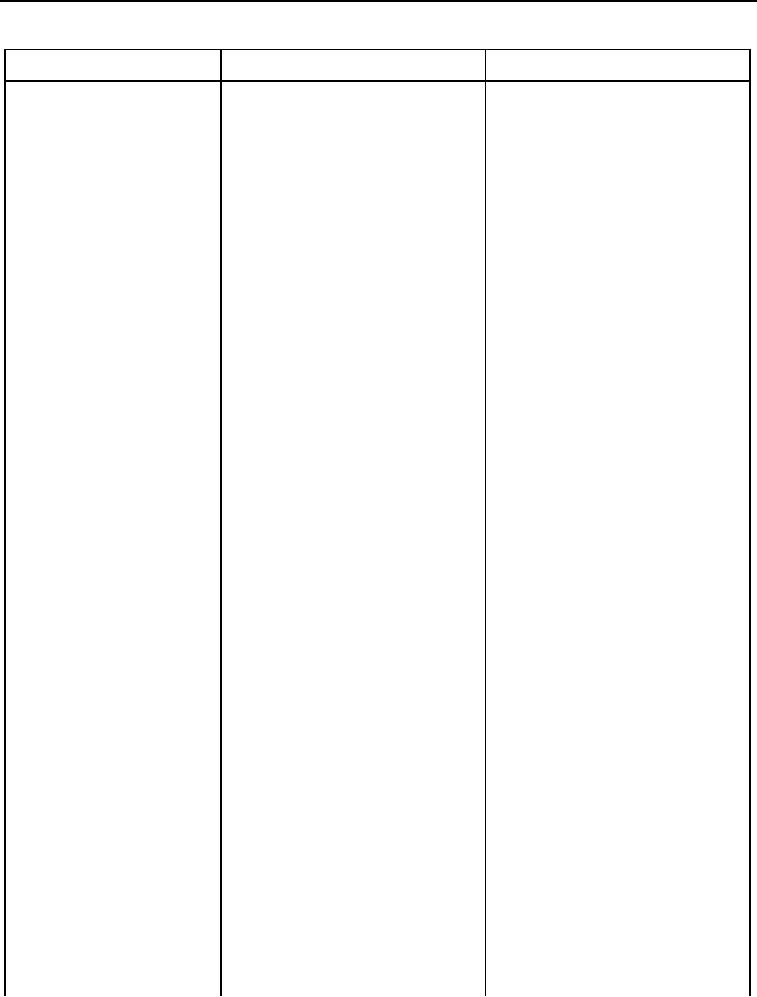

Table 1. Cab Electrical Troubleshooting Procedures - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

4. One or Both Headlights

3. Turn control indicator switch to

Headlight or Headlights Do Not

Do Not Operate in High

position SER. DRIVE, dimmer

Operate in High Beam - Repeat trou-

Beam - Continued

switch to high beam (TM 5-3805-

bleshooting from the beginning.

293-10) and verify headlights

Both Headlights Operate in High

operate in high beam.

Beam - Troubleshooting complete.

Test Step 8. Check for Open Cab

Lower Wiring Harness.

1. Remove head lamp relay (WP

0009, Figure 298) from head lamp

relay socket (WP 0009, Figure

299).

2. Connect jumper wire between

head lamp relay socket (WP

0009, Figure 299) terminals C14

and E13.

3. Using digital multimeter, measure

Resistance Less Than 5.0 Ohms -

resistance between cab lower wir-

Proceed to Test Step 9.

ing harness connector P-C11 (WP

Resistance 5.0 Ohms or Greater -

0009, Figure 286) terminal 6 and

Replace cab lower wiring harness

machine ground. Resistance

(WP 0266).

should be less than 5.0 ohms.

Remove jumper wire between head

lamp relay socket (WP 0009, Figure

299) terminals C14 and E13.

Install handleable relay (WP 0009,

Figure 298) to handleable relay

socket (WP 0009, Figure 299).

Connect the control indicator harness

connector PE-C11 (WP 0009, Figure

287) to cab lower wiring harness con-

nector P-C11 (WP 0009, Figure 286)

(WP 0283).

Connect the connector AZ-C1 (WP

0009, Figure 387) to left headlight and

install headlight assembly (WP 0197).

Proceed to step 4.

4. Turn control indicator switch to

Headlight or Headlights Do Not

position SER. DRIVE, dimmer

Operate in High Beam - Repeat trou-

switch to high beam (TM 5-3805-

bleshooting from the beginning.

293-10) and verify headlights

Both Headlights Operate in High

operate in high beam.

Beam - Troubleshooting complete.

0023-23