TM 5-3805-293-23-2

0023

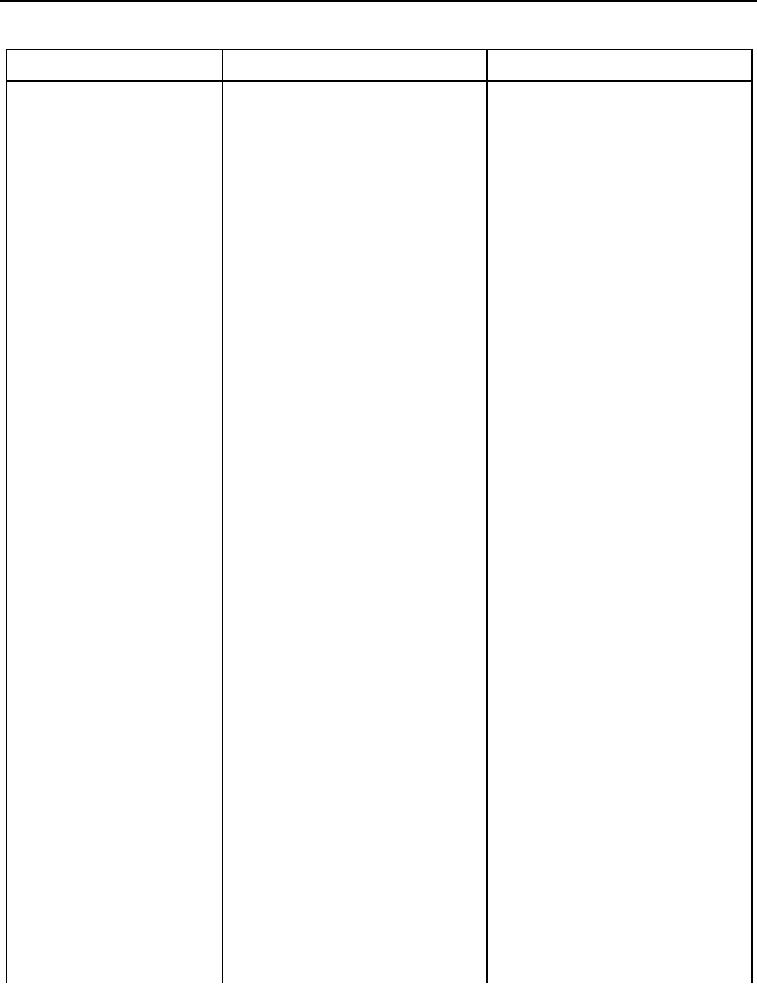

Table 1. Cab Electrical Troubleshooting Procedures - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

3. Blackout Lamp Does not

2. Using digital multimeter, measure

Resistance Less Than 5.0 Ohms -

Operate - Continued

resistance between blackout light

Replace cab lower wiring harness

wiring harness connector AAA-C1

(WP 0266).

(WP 0009, Figure 381) terminal 1

Remove jumper wire between AAA-

and machine ground. Resistance

C2 (WP 0009, Figure 380) terminals 1

should be less than 5.0 ohms.

and machine ground.

Connect the blackout light harness

connector AAA-C2 (WP 0009, Figure

380) to blackout light (WP 0204).

Proceed to step 3.

Resistance 5.0 Ohms or Greater -

Replace blackout light wiring harness

(WP 0204).

Connect the control indicator harness

connector PE-C11 (WP 0009, Figure

287) to cab lower wiring harness con-

nector P-C11 (WP 0009, Figure 286)

(WP 0283).

Proceed to step 3.

3. Turn control indicator switch to

Blackout Lamp Does Not Operate -

position B.O. DRIVE (TM 5-3805-

Repeat troubleshooting from the

293-10) and verify blackout lamp

beginning.

operates.

Blackout Lamp Operates - Trouble-

shooting complete.

Test Step 8. Check for Shorted

Control Indicator Wiring Harness.

1. Remove jumper wire between

AAA-C2 (WP 0009, Figure 380)

terminals 1 and machine ground.

2. Using digital multimeter, measure Continuity - Proceed to Test Step 9.

for continuity between control

No Continuity - Proceed to Test Step

indicator harness connector PE-

10.

C11 (WP 0009, Figure 287) termi-

nal 1 and machine ground. There

should be no continuity.

Test Step 9. Check for Shorted

Control Indicator Switch.

1. Disconnect the control indicator

harness connector PE-C10 (WP

0009, Figure 288) from control

indicator switch (WP 0009, Figure

289).

0023-16