TM 5-3805-293-23-2

0022

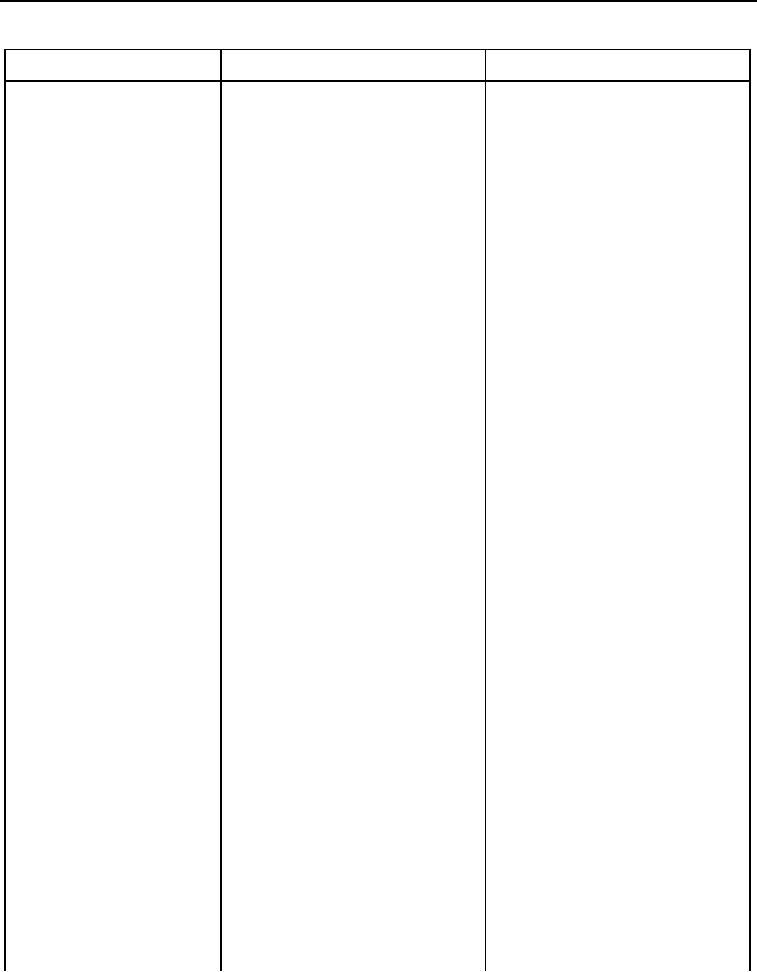

Table 1. Cab Heating, Air Conditioning, and 12 Volt Power Inverter Troubleshooting Procedures - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. Heater Does Not Blow

9.

Using digital multimeter, test for

Resistance 5.0 Ohms or Less -

Warm When Tempera-

continuity between harness con-

Replace 12 volt power inverter (WP

ture Control Panel Is Set

nector R-C22 (WP 0009, Figure

0265).

On Maximum Heat - Con-

386) terminal 10 and harness

Connect upper cab wiring harness

tinued

connector R-C23 (WP 0009, Fig-

connector R-C22 (WP 0009, Figure

ure 277) terminal 5.

386) to HVAC control panel (WP

Resistance should be less than

0009, Figure 385) (WP 0265).

5.0 ohms.

Proceed to step 10.

Resistance More Than 5.0 Ohms -

Replace cab upper wiring harness

(WP 0265).

Proceed to step 10.

10. Operate machine until engine

reaches normal operating temper-

ature (TM 5-3805-293-10).

11. Turn fan speed switch to maxi-

mum speed (TM 5-3805-293-10).

12. Turn temperature control to the

No Warm Air From Air Vents -

warmest setting and verify warm

Repeat troubleshooting from the

air exiting from air vents.

beginning.

Warm Air From Air Vents - Trouble-

shooting Complete.

Test Step 4. Test Water Valve Actu-

ator +12 Volt Power and Ground

Circuits.

1. Connect upper cab wiring har-

ness connector R-C22 (WP 0009,

Figure 386) to HVAC control

panel (WP 0009, Figure 385) (WP

0265).

2. Disconnect cab lower wiring har-

ness harness connector CM-C7

(WP 0009, Figure 271) from water

valve actuator (WP 0009, Figure

270) (WP 0294).

3. Turn battery disconnect switch

and ignition switch to the ON posi-

tion (TM 5-3805-293-10).

4. Using digital multimeter, test for

Voltage Between 10 to 14 Volts -

voltage between harness connec-

Proceed to step 5.

tor CM-C7 (WP 0009, Figure 271)

Voltage Less Than 10 Volts - Pro-

terminal A and machine ground.

ceed to Test Step 5.

Voltage should be 10 to 14 volts.

0022-5