TM 5-3805-293-10

0013

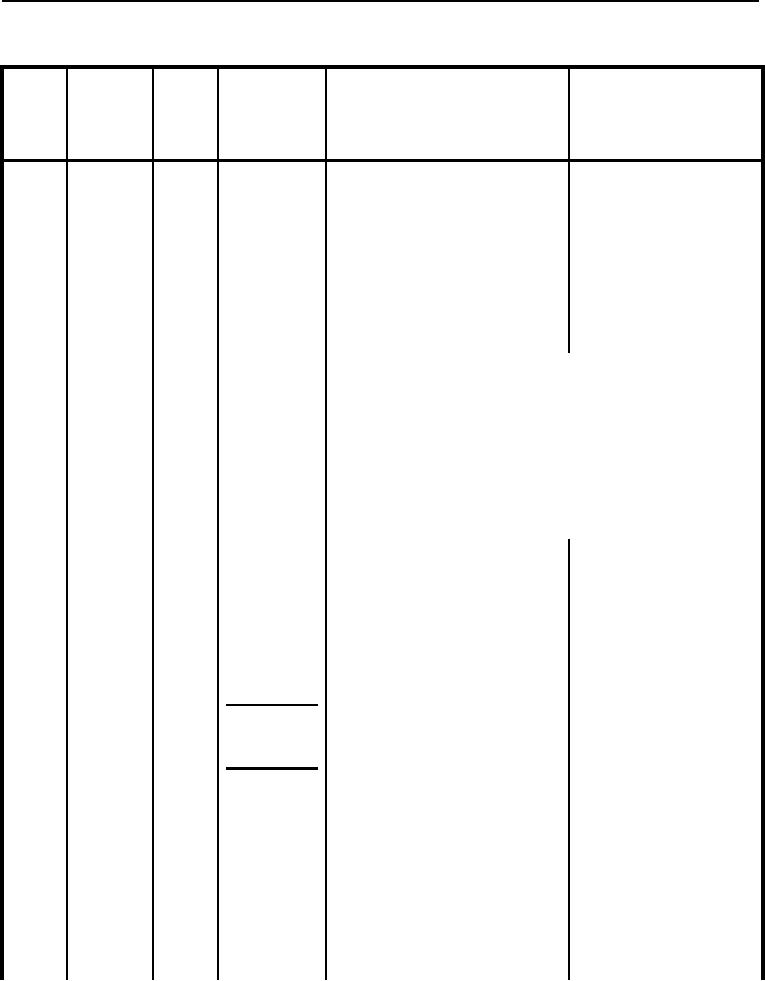

Table 1. Preventive Maintenance Checks and Services (PMCS)

with Lubrication Information - Continued.

LOCATION

ITEM TO

ITEM

MAN-

CHECK/

NOT FULLY MISSION

NO.

INTERVAL HOURS

SERVICE

PROCEDURE

CAPABLE IF:

19

Before

Engine

a. Visually check for loose,

Class III leaks or damage

that would impair operation

Compartment

damage, cracked components, or

are evident.

evidence of leaks.

b. Close right front access door.

a. Check hoses and connections Class III oil or hydraulic fluid

20

Before

Below

leaks are present. Any fuel

below right side of operator

Operator

compartment for damage or leaks. leakage is evident. Damage

Compartment

that would impair operation

b. Check cables for fraying or

is evident.

damage.

WARN I N G

21

Before

Right Front

Tire

Improperly inflated tires can cause excessive heat buildup

resulting in blowouts. Failure to follow this warning may

result in serious injury or death to personnel, or damage to

equipment.

If tire pressure is more than 4 psi low, tires must be

inflated in a safety cage. Notify Field Level Maintenance.

Failure to follow this warning may result in serious injury or

death to personnel, or damage to equipment.

Tire pressure appears low.

Visually check tire for

underinflation.

22

Before

Lights

Check right front work light,

Missing or damaged

headlight, blackout drive light,

components if necessary

blade work light, and front turn

for mission.

signal light for missing or damaged

components.

CAB

INTERIOR

23

Before

Battery

Turn battery disconnect switch to

Disconnect

ON position.

Switch

24

Before

Fire

a. Visually check for missing or

Fire extinguisher is missing

Extinguisher

damaged fire extinguisher. Ensure

or damaged.

it is securely stowed in mounting

bracket.

b. Check gauge for pressure

Pressure gauge needle is in

reading in green area on gauge.

red area.

0013-13