TM 5-3805-263-14&P-3

Brakes Balanced (Left Side)

When the air pressure under relay piston (12) is near the

air pressure on top of it, the relay piston (12) moves to

close the passage (15) and stops the flow of air from

supply port (17) to delivery port (18). Exhaust port (21)

will stay closed as the air pressure for the brakes on the

left side of the machine becomes the same as the air

pressure for the brakes on the right side of the machine.

When brake applications are made gradual, a

balance position in the section for the brakes on the right

side of the machine is reached when the air pressure at

the delivery port (10) is the same as the pressure of the

operator's foot on the pedal. A balance position is

reached in the section for the brakes on the left side of

the machine when the air pressure under the relay piston

(12) gets close (approaches) the air pressure above the

relay piston (12).

When the brake pedal is pushed all the way down,

both the inlet and exhaust valves (9) and (20) are open

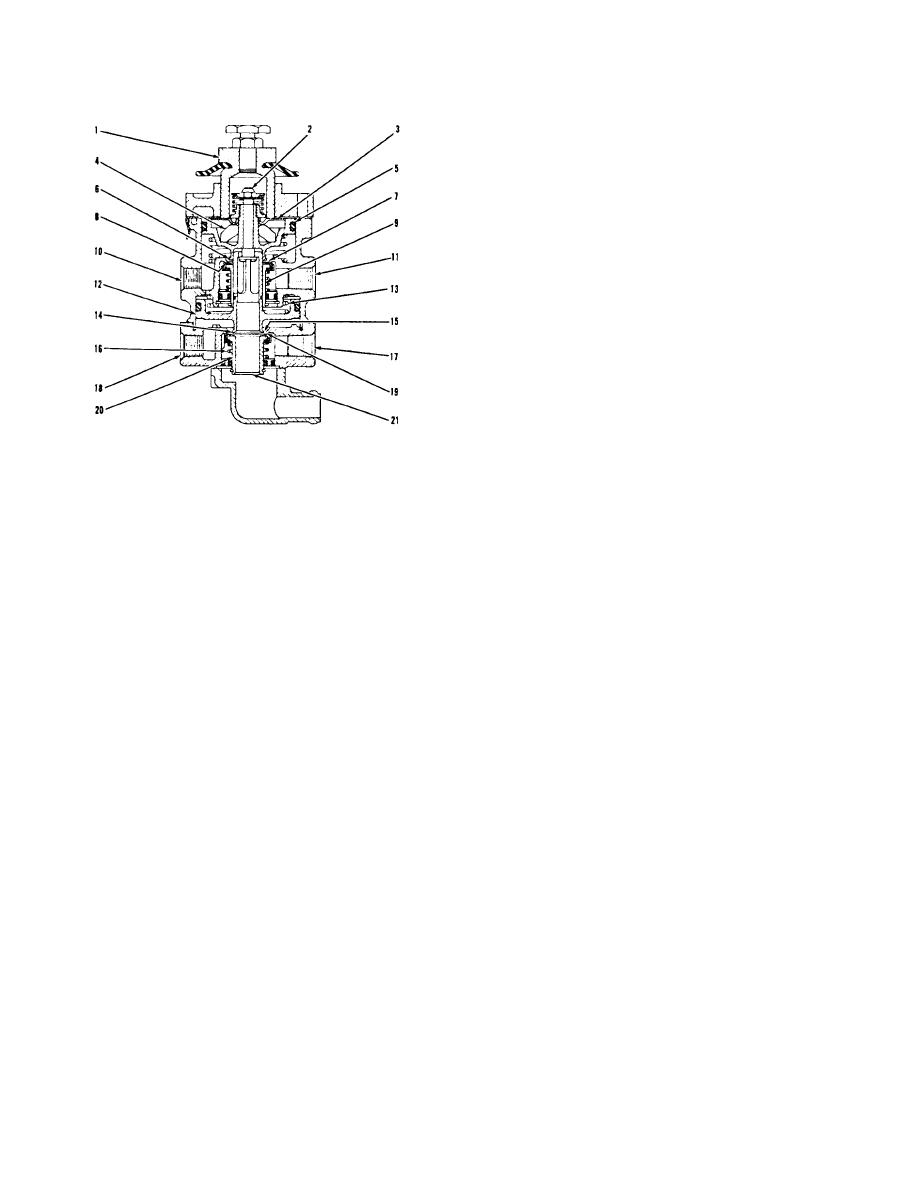

CONTROL VALVE FOR SERVICE BRAKES

and full air pressure for the air tanks go to the brakes for

1.

Plunger.

2.

Screw.

3.

Spring seat.

4.

both sides of the machine.

Rubberspring. 5. Piston. 6. Seat. 7. Exhaust passage.

8. Seat. 9. Inlet and exhaust valve. 10. Delivery port.

SERVICE BRAKES

11. Supply port. 12. Relay piston. 13. Spring. 14.

The power from the differential is through drive chain (3)

Exhaust seat. 15. Exhaust passage. 16. Spring. 17.

to sprocket (1). The sprocket turns wheel spindle (5),

Supply port. 18. Delivery port. 19. Seat. 20. Inlet and

hub (2) and discs (8) in wheel spindle housing (13). The

exhaustvalve. 21. Exhaust port.

drive wheels are connected to flange (14) of wheel

spindle (5).

Loss of Brakes for Right Side

The disc-type brakes, one in each wheel spindle

Should air pressure in the circuit for the brakes on the

housing, are operated by air pressure from the relay

right side of the machine be lost, the brakes for the left

valves. Each brake is made up of discs (7) connected to

side of the machine can still be applied. As the brake

spindle housing (13) and discs (8) connected to hub (2).

pedal is pushed, and there is no air pressure at supply

The cooling of the brakes is through the oil in the drive

port (11) and delivery port (10), there will be no brakes

tandems.

for the right side of the machine. Piston (5) will

When the control valve opens, pressure air goes

mechanically move relay piston (12) to close inlet and

through port (10) into air compartment (9). Air then

exhaust valve(20) and let air pressure from supply port

moves piston (11) against discs (7) and (8). The piston

(17) go out delivery port (18) to the brakes for the left

pushes the discs against cover (6). As the air pressure

side of the machine.

becomes higher, the force of piston (11) pushing against

the discs causes friction between the discs. As the

Brakes Balanced (Right Side)

friction becomes greater, discs (8), hub (2), and wheel

When the air pressure at the delivery port (10) is the

spindle (5) will start to slow down, since discs (7) and

same as the mechanical force of the brake pedal, piston

wheel spindle housing (13) cannot turn. This is the

(5) will move and the inlet and exhaust valve (9) will

brake ON position, but the brakes are not fully engaged.

close and stop the flow of air from supply port (11). The

inlet and exhaust valve (20) will stay closed and will not

let air pressure go out through exhaust port (21).

3-118