TM 5-3805-263-14&P-3

AIR SYSTEM AND BRAKES WITH

Air from the air tank (6) goes to control valve (18). In

TWO SECTION AIR TANK

the LOCK position, air goes through the control valve to

the spring side of the piston in the lock pin housing. The

The machine is normally operated with the differential

force of the springs and the pressure air hold the lock-pi-

lock in the automatic LOCK position. To release the

i-n the LOCK position. In order to move the link bar and

differential lock, the steering panel console switch is

the circle to another location, the lever on control valve

pushed down.

(18) first must be moved to the INDEX position. This

When the panel switch is down (function indicator

releases the air from the spring side of the piston. The

light is off), a spring on the control valve holds the valve

lever is then moved to the RETRACT position. Pressure

spool in a position to let part of the oil from the No. 6

air is sent to the other side of the piston to pull the lock

clutch go to the differential lock. When the switch is

pin out of the lock plate against the force of the springs.

pushed up (function indicator light goes on) the solenoid

The centershift cylinder and the lift cylinders are then

moves the valve spool against the force of the spring to

operated to move the link bar and the circle to the

stop the flow of oil from the No. 6 clutch. With the valve

desired location.

spool in this position, a passage in the lock valve is also

opened to release the oil in the differential lock.

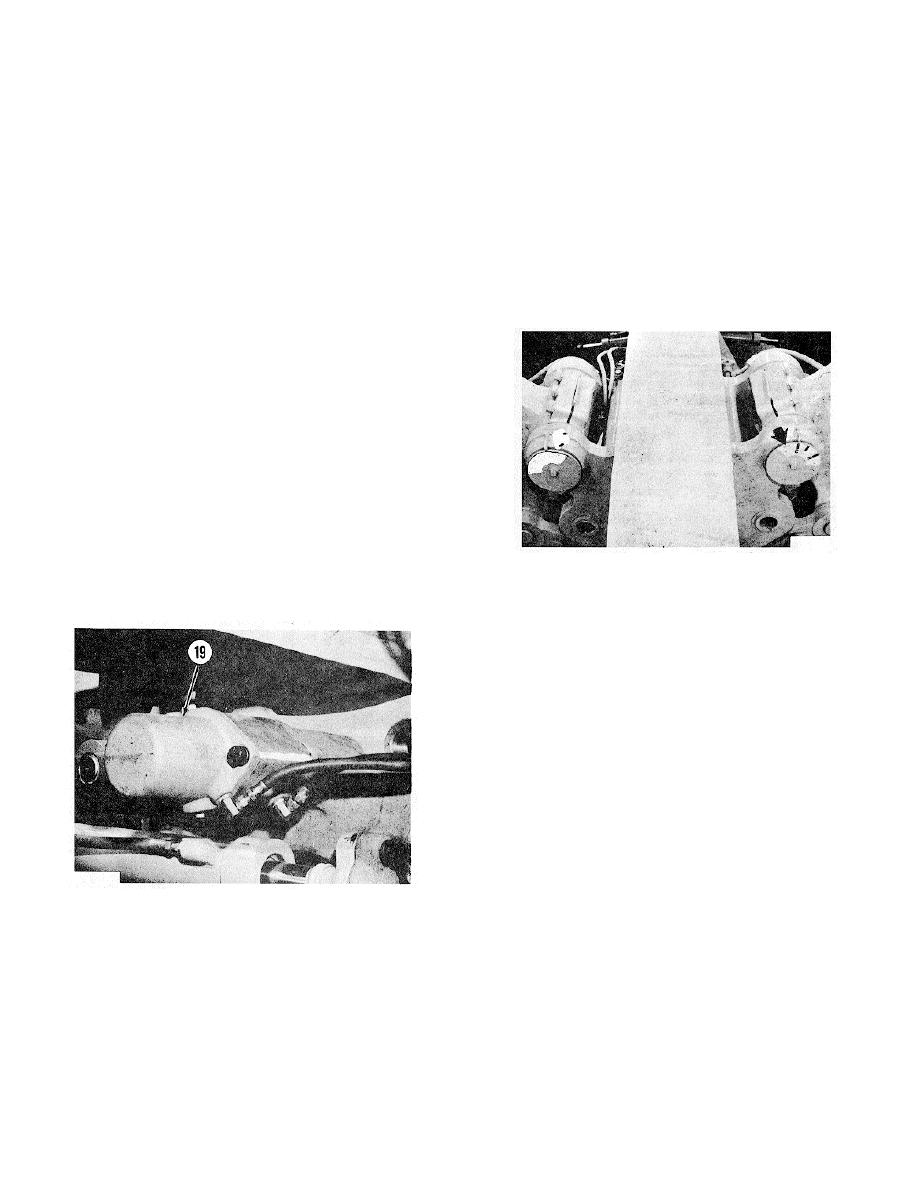

Centershift Lock

The location of centershift lock pin (19) is on the front

of the link bar. When lock pin (19) is not engaged with

the lock plate, the link bar and the circle can be moved to

put the blade in the correct position for the job

application.

Centershift control valve (18) is on the console to the

right of the seat. This control valve controls the flow of

air to the lock pin. The machine is normally operated

with the control valve in the LOCK position. Since the

CENTERSHIFT INDICATOR

lock pin cannot be seen by the operator, indicators on

pin part of the way into the lock plate. The lever on the

the rear of the lock plate show the operator when the

control valve is then moved to the LOCK position to

lock pin is in alignment with the correct hole in the lock

again send pressure air to the spring side of the piston.

plate.

The spring force and the pressure air will then fully

engage the lock pin in the lock plate.

CENTERSHIFT LOCK PIN

19. Centershift lock pin.

3-115