TM 5-3805-261-23-2

BLADE TIP CYLINDER REPAIR - CONTINUED

0334 00

ASSEMBLY - CONTINUED

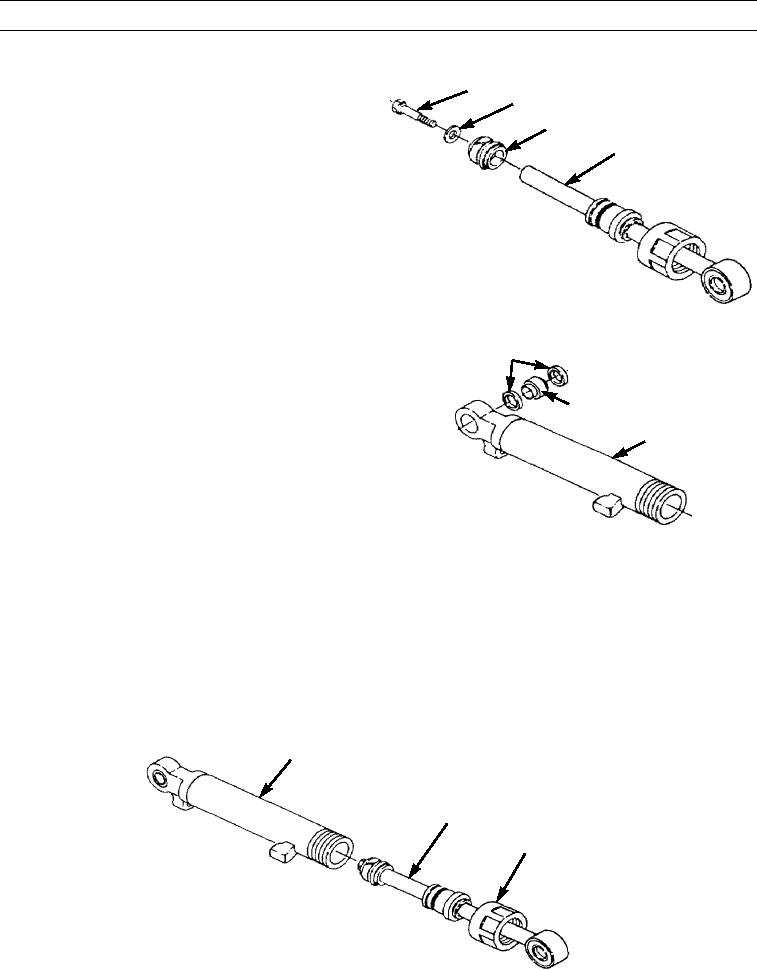

10.

Install piston (10) assembly on rod (3).

8

9

11.

Apply thin coat of thread lubricant to threads of bolt

10

(8) and install washer (9) and bolt to end of rod (3).

Tighten bolt to 800 lb-ft (1,085 Nm).

3

397-1987

12.

If removed, install one of two rings (6) to a depth of

6

0.15 in. (3.8 mm) from outer surface of cylinder (2).

13.

If removed, install new bearing (7) in center of cylin-

7

der (2).

2

14.

If removed, install other ring (6) next to bearing (7).

Depth of ring to outer surface of cylinder (2) should be

0.15 in. (3.8 mm).

397-1986

NOTE

Apply thin coat of grease to outside of head assembly, inside of sleeve and inside of cylinder.

15.

Install rod cylinder (3) assembly into cylinder (2).

NOTE

Tighten sleeve with rod assembly fully extended. This will keep cylinder, piston, and head in alignment.

16.

Install sleeve (5) on cylinder (2). Tighten sleeve to 450 lb-ft (610 Nm).

2

3

5

397-1985

0334 00-6