ELECTRICAL TROUBLESHOOTING

TM 5-3805-263-14&P-3

EMS PANEL

Continuity

No Continuity

The harness is good. Replace the operator panel.

Use the electrical schematic or the simplified schema-

tic to find the harness with an open (broken) wire

Replace the harness.

3. Check for continuity between the ground connection on the oil pressure switch (B/W

wire) and machine ground. Use a continuity tester or a digital multimeter.

Continuity

No Continuity

The ground connection is good. Either the pressure

Replace the harness or fasten a wire from the switch

switch has a failure in the open position or there is a

ground connection to machine ground.

failure in the oil pump. Go to Step 4.

4. Turn the fuel OFF.

Remove the oil pressure switch and put a thumb over the opening.

Have another serviceman turn the start switch to the START position so that the

starter motor turns the engine. (Do not turn the engine for more than 30 seconds.)

An increase in oil pressure must be felt.

Oil Pressure Is Felt

Oil Pressure Is Not Felt

Install a pressure gauge in the opening for the pres-

Make repairs as necessary.

sure switch and make a test for oil pressure. If oil

pressure is correct, make a replacement of the oil

pressure switch. If oil pressure is not correct, make

repairs as necessary.

Engine Coolant Temperature Or

Hydraulic Oil Temperature Indicator

Follow the instructions given at the first of the section on the monitoring system, to

make sure the system is cool enough for the indicator to turn OFF. If the indicator

does NOT turn OFF, make a check of the electrical system as follows:

1. Disconnect the control wire from the temperature switch of the indicator that is ON

(See TABLE 4).

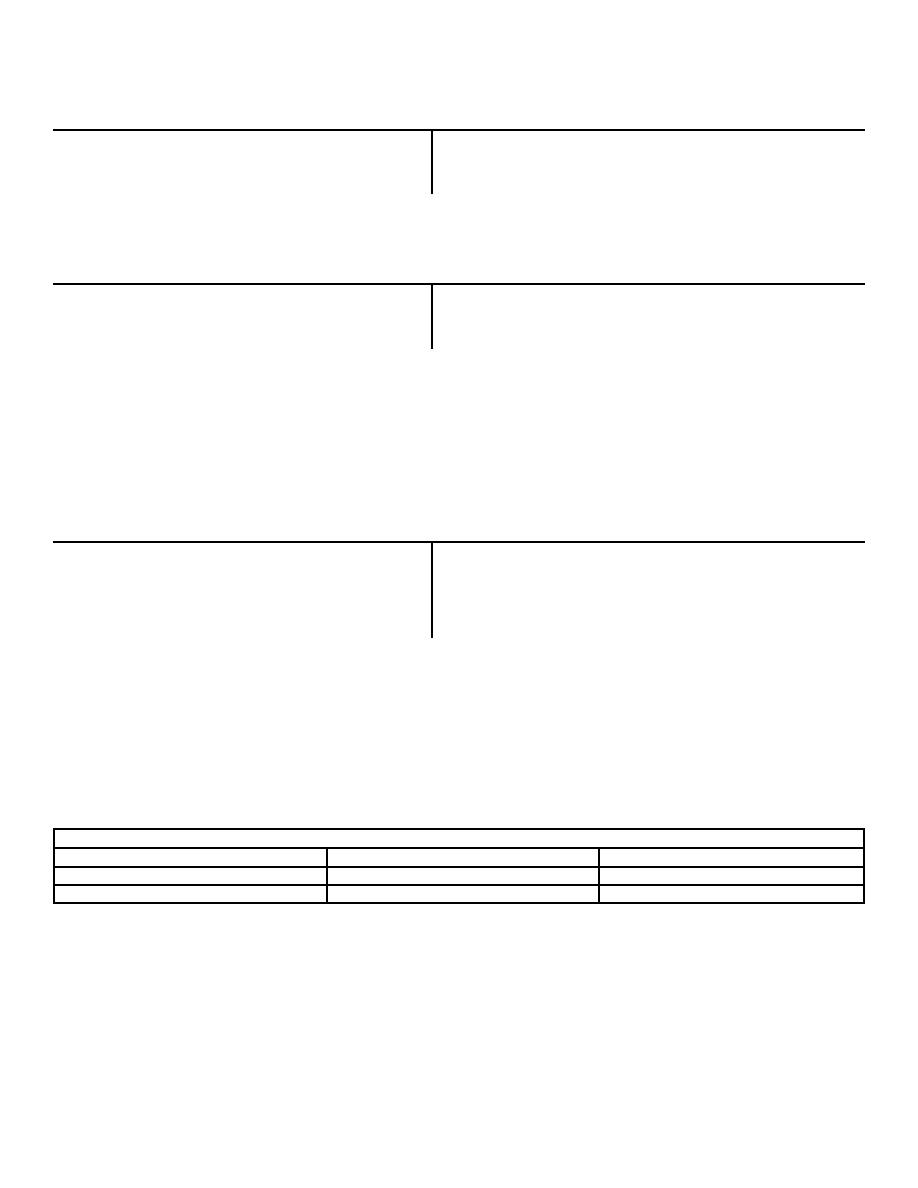

TABLE 4

Indicator

Switch

Control Wire Color

Engine Coolant Temperature

7N9785

R/W

Hydraulic Oil Temperature

3T 190

Y / PU

4-38