ELECTRICAL TROUBLESHOOTING

TM 5-3805-263-14&P-3

EMS PANEL

PROBLEM B: An Indicator That Must Be ON is NOT ON.

Possible Causes: a. Switch is bad.

b. Wire, in the harness, that goes to the switch, is grounded or shorted

to another wire in the harness that is at ground potential.

c. Operator panel is bad.

TROUBLESHOOTING

With the test switch OFF and the engine OFF, the oil pressure indicator and the

alternator indicator must be ON. If the brake system air pressure is below about 62

psi (430 kPa), this light will be ON. Check these conditions before servicing panel.

If the alternator indicator is NOT ON, replace the operator panel.

If the oil pressure or brake pressure is NOT ON, do the following:

1. Remove the control wire from the switch (sensor). (See Table 2) The indicator must

turn ON.

Indicator Turns ON

Indicator Does Not Turn ON

The switch (or switches) is bad. Replace the switch

The harness has a short, or the operator panel is bad.

(or switches).

Go to Step 2.

2. Put tape on the control that was removed from the switch so that it can not be

grounded to the machine (see Table 2).

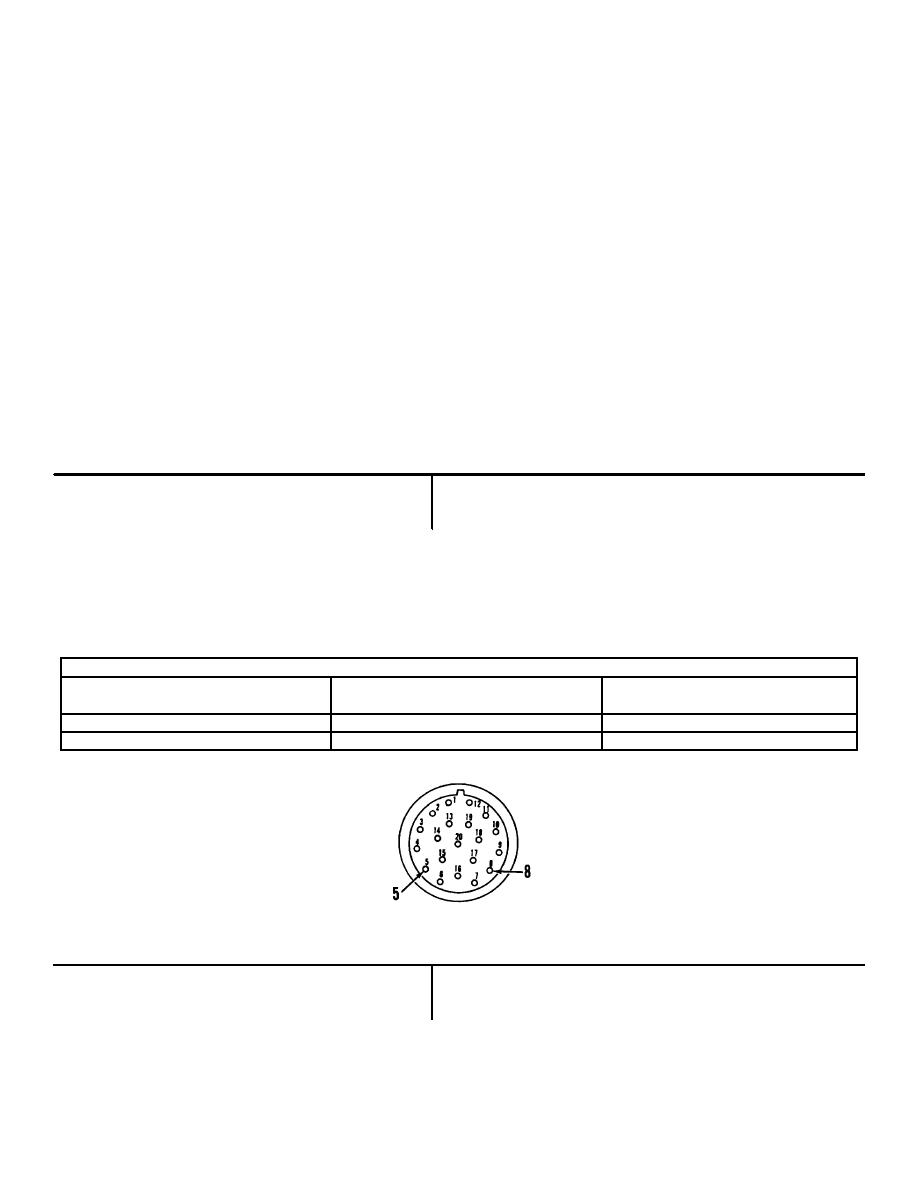

Disconnect the harness plug from the operator panel. Use the continuity tester or a

digital multimeter to check for continuity between connections 2 and control wire to be

checked (see Table 2).

TABLE 2

Control Wire Color

Harness Plug Connection

at Switch

Switch

at Operator Panel

GY/R

Oil Pressure

5

Y

Brake Pressure

8

Continuity

No Continuity

There is a ground or a short in the harness. Replace

Replace the operator panel.

the harness.

4-32