TM 5-3805-261-34

2-3.

GENERAL MAINTENANCE INFORMATION.

1.

Hydraulic System Maintenance.

CAUTION

Make sure that no hose is twisted, stretched or kinked. Hoses that are twisted or

kinked can close off flow through the system and lead to component failure.

(16) Screw on both tube nuts with your fingers to position tubing and clamps correctly before tightening tube nuts.

(17) Put anti-seizing tape MIL-T-27730 on pipe (tapered) threads. Do not put tape on first two threads.

(18) Operate the system being worked on and check the system for leaks at all connections that were loosened. If

a connection leaks, unscrew a full turn, then tighten. If it is still leaking, replace leaking parts.

(19) Always look carefully at equipment for likely signs of trouble while doing routine work. If hydraulic oil is leaking

down on harnesses and connectors, repair the leak at once. Tie down any harness that is free to move and rub against

metal. If you look for possible trouble spots and make repairs at once, you can cut down on repair time and extra work.

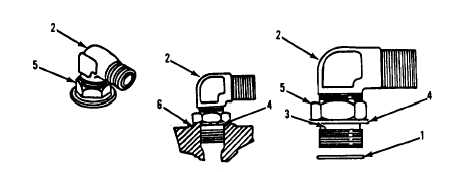

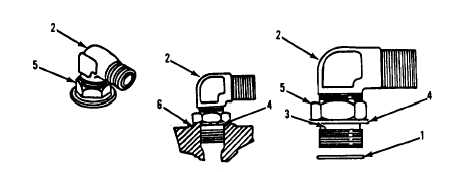

(20) Installing adjustable fittings.

(a)

Put a light coat of lubricant, same as lubricant in system being worked on, on packing (1, Figure 2-3).

Slide packing (1) on fitting (2) so that packing (1) is seated in groove (3) against washer (4) as far as it will go.

(b)

Turn lock nut (5) clockwise until it touches washer (4).

(c)

Screw fitting (2) into boss (6) until washer (4) touches boss (6).

(d)

Turn fitting (2) counterclockwise, up to one full turn, until desired position is reached.

(e)

Whenever possible, hold fitting (2) in position with one wrench and tighten lock nut (5) clockwise with

other wrench.

Figure 2-3.

2-11