TM 5-3805-261-20

PRINCIPLES OF OPERATION.

1-32.

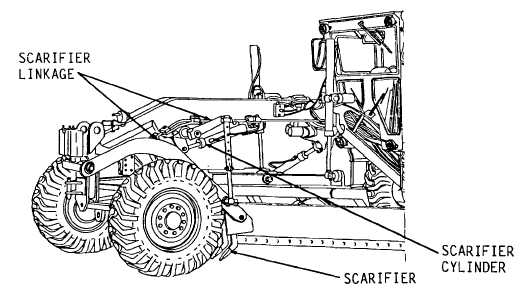

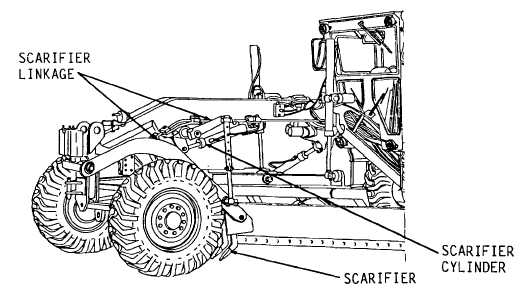

SCARIFIER ASSEMBLY (Figure 1-71). The scarifier assembly uses a hydraulic cylinder to move the scarifier

upward or downward. The scarifier control lever is located in the lever group at the right side of the steering console in the

cab. Refer to TM 5-3805-261-10 for scarifier operating instructions and control lever location. Refer to paragraph 1-29 for

description of control valve and lock check valve.

When the engine is running, the oil from the variable displacement pump goes through the relief and pressure reduction

valve through lines, to the control valve for the scarifier cylinder. The pressure of the oil in lines can get as high as the

pressure setting of the relief valve. When the control valve for the scarifier cylinder is not being used, the pressure of the

oil in lines is 2150 psi.

When the engine is running, and the scarifier is not being used, the pressure of the pump oil in lines to the control valve is

approximately 2150 psi. The oil in lines in passage is open to the tank and the pressure of the oil in these lines is the same

as the oil in the tank. Lock check valve stops the oil in the lines between valve and cylinder and the rod in the cylinder

cannot move. The pressure of the oil in lines is the same as the oil in the tank.

When the scarifier control valve lever is held in the LOWER position, the pump oil goes through control valve through lines

and lock check valve into the head end of cylinder. The oil in the head of cylinder pushes the piston and rod out of the

cylinder which moves the scarifier down. When more force is needed to lower the scarifier, there is an increase in the

pressure of the pump oil to the head end of cylinder. When the pressure of the pump oil goes to 1500 psi, the oil moves

the shuttle valve in the pump and the oil pressure from the pump can go to approximately 3500 psi.

Figure 1-71.

1-57 (1-58 blank)